AXE MAINTENANCE AND SAFETY

-

Proper Technique & Safety

When splitting, use a firm and stable chopping surface to reduce the risk of injury or damage to your tool. Never split wood against the ground. Take care to avoid striking the handle against logs or other objects, which can happen in the event of a miss swing, and is the leading cause of damaged handles. If your axe blade becomes stuck in a log, rock it back and forth in line with the blade. Never twist side to side, as this may break your handle. Use additional caution when splitting frozen or knotty wood, as it can be very hard and may damage the tool or cause the blade to bounce off.

Use common sense when splitting wood - not all wood can be split with an axe. Wood must be selected, seasoned, and ready to split in order for the tool to function as intended. Relying on brute strength and simply striking as hard as possible, as opposed to using proper technique combined with the right wood, may lead to early handle breaks.

Accidental miss swings and flying debris can cause serious injury to the eyes, feet, and body. Eye protection, steel-toed boots, and proper clothing and protective gear should always be worn. Spectators should maintain a safe viewing distance. The back side of axes and hatchets (referred to as the "poll" or "butt") should not be used as a striking surface. Only sledgehammers should be used to pound in steel wedges. Never use an axe, maul, or hatchet if you are tired, on medication, or intoxicated. -

The Handle

Common causes for broken handles, aside from blatant misuse, are hard overstrikes, lateral (side to side) twisting when lodged in wood, and drying out. When neglected, a handle is more likely to dry out, become brittle, and crack. Proper care will significantly prolong the handle’s life. Maintain and protect your axe handle with boiled linseed oil. It is recommended, even with a new axe, to apply multiple coats of boiled linseed oil to heavily saturate your handle. For a proper finish, this should be done in stages over a couple weeks, allowing each coat several days to fully dry. Doing this will help to ensure the handle stays healthy, flexible, and retains a proper moisture level.

This will form a strong protective finish that will endure years of service. Use 150 grit sandpaper to smooth out chips and restore a damaged finish, as necessary, while re-oiling afterwards. Keep the eye saturated with linseed oil to prevent the wood from drying out and shrinking, which can cause a head to loosen. -

The Edge

Become familiar with proper sharpening techniques. Keep the edge sharp while maintaining the original bevel. Use a sharpening stone to sharpen your edge. Grinders or sanders can be used with extreme caution, as overheating can alter the steel temper.

Our dual-grit Axe Sharpening Stone features a coarse side of 80 grit to restore dull edges, and a fine side of 220 grit for finer sharpening. This combination can bring a dull blade to a razor edge. -

Sheath

Always use a sheath to protect the axe blade. This will not only help protect against injury to the user, but also from accidental damage to the blade’s edge. Leather oils or conditioners should be used on occasion to maintain and reinvigorate the leather of your sheath. Neglected leather, over time, will begin to harden, crack, or fall apart.

-

Storage

Store your axe in a cool, dry place. Excessive exposure to moisture and the elements may cause damage over time. Do not store in direct sunlight, or near a stove, fireplace, or other heat source. This can cause significant damage to handles by lowering humidity levels in the wood. After using your axe, always clean and oil the head.

-

Rust Protection

High grade carbon steel is susceptible to rusting over time. Rust can be prevented by keeping the axe head well oiled. If rusting does occur, use steel wool or an abrasive to remove the rust, and then wipe down with a metal protecting oil. Afterwards, our Axe Balm can be applied to serve as a protective layer against the elements, which is safe to use on metal, wood, and leather.

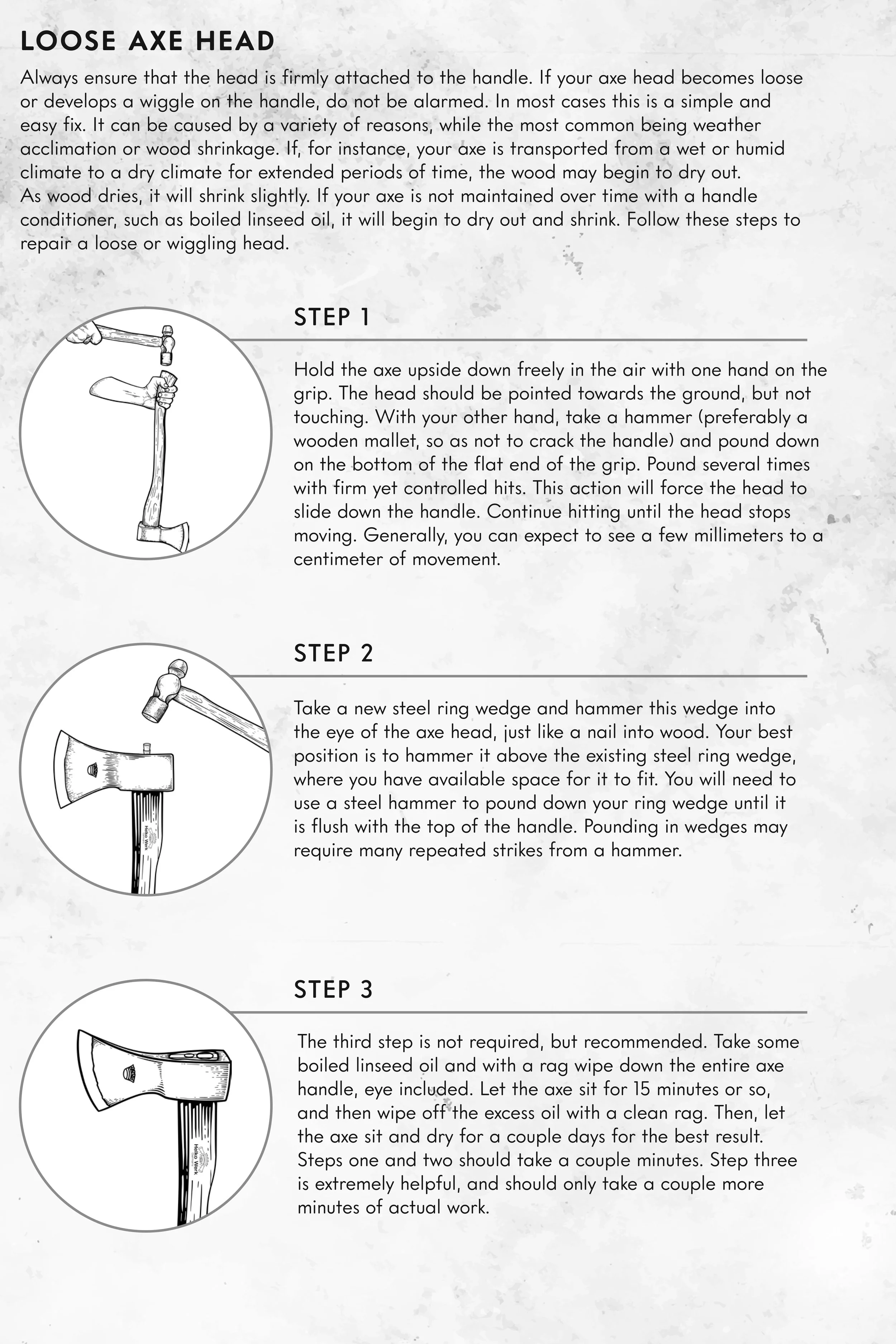

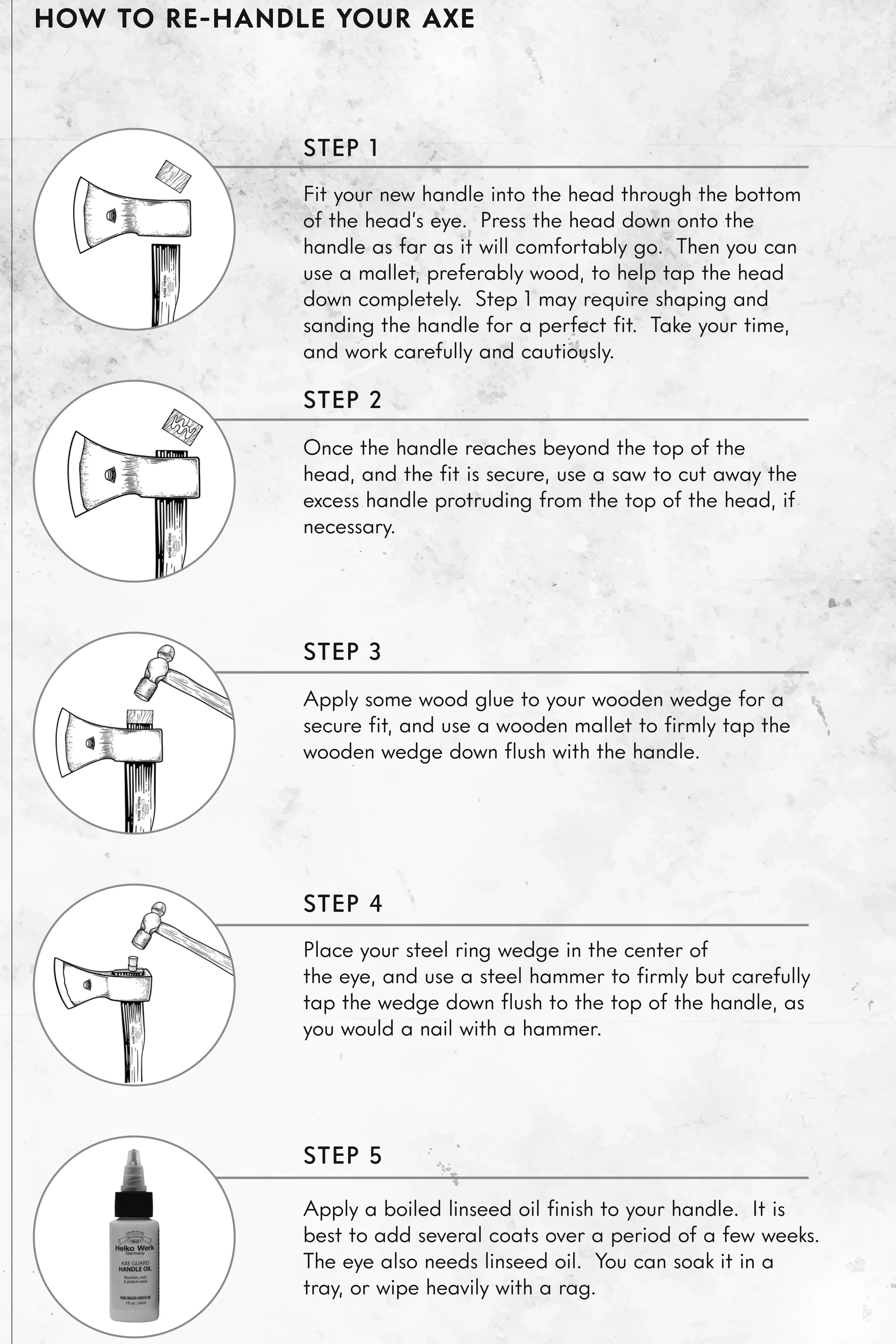

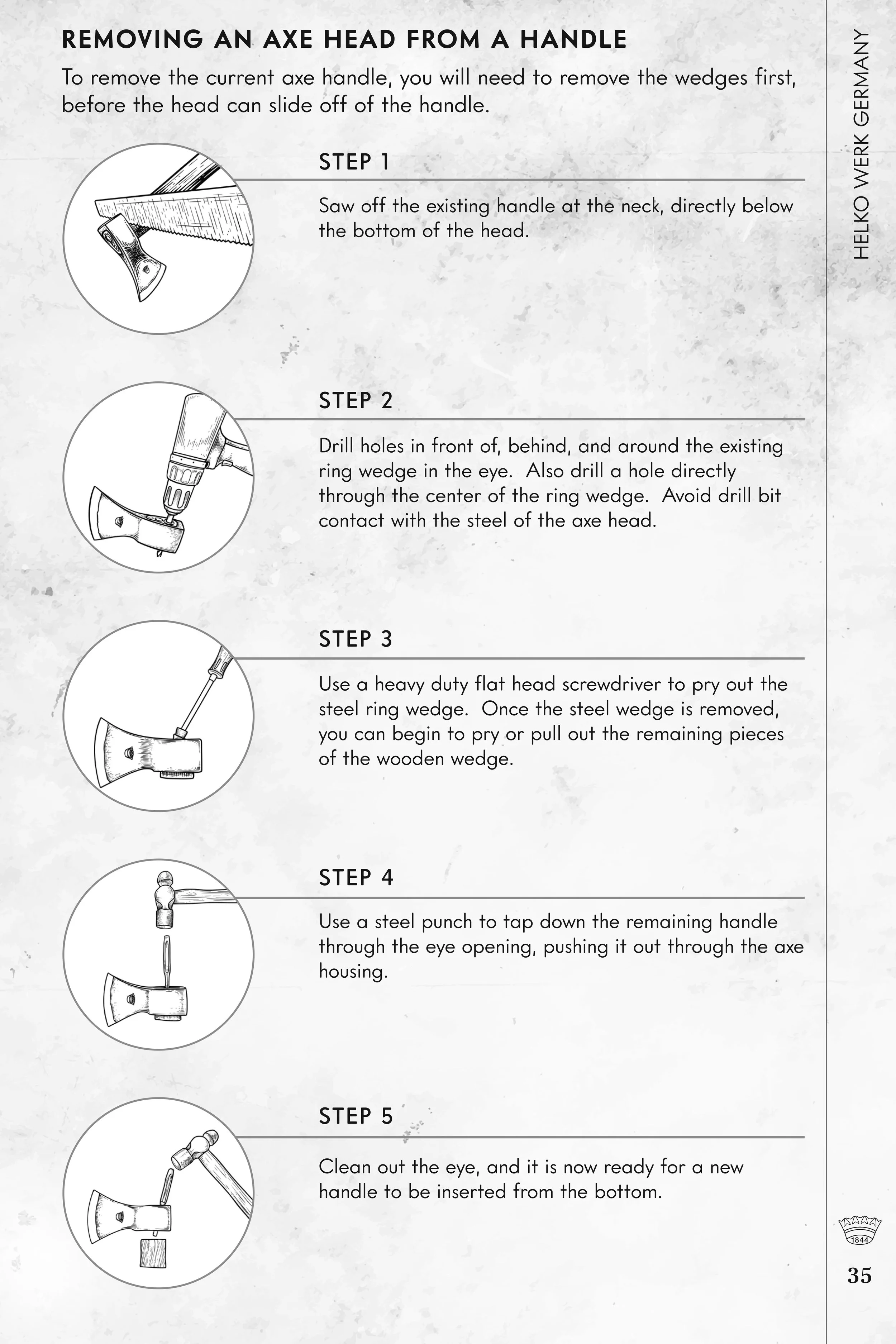

Repairs

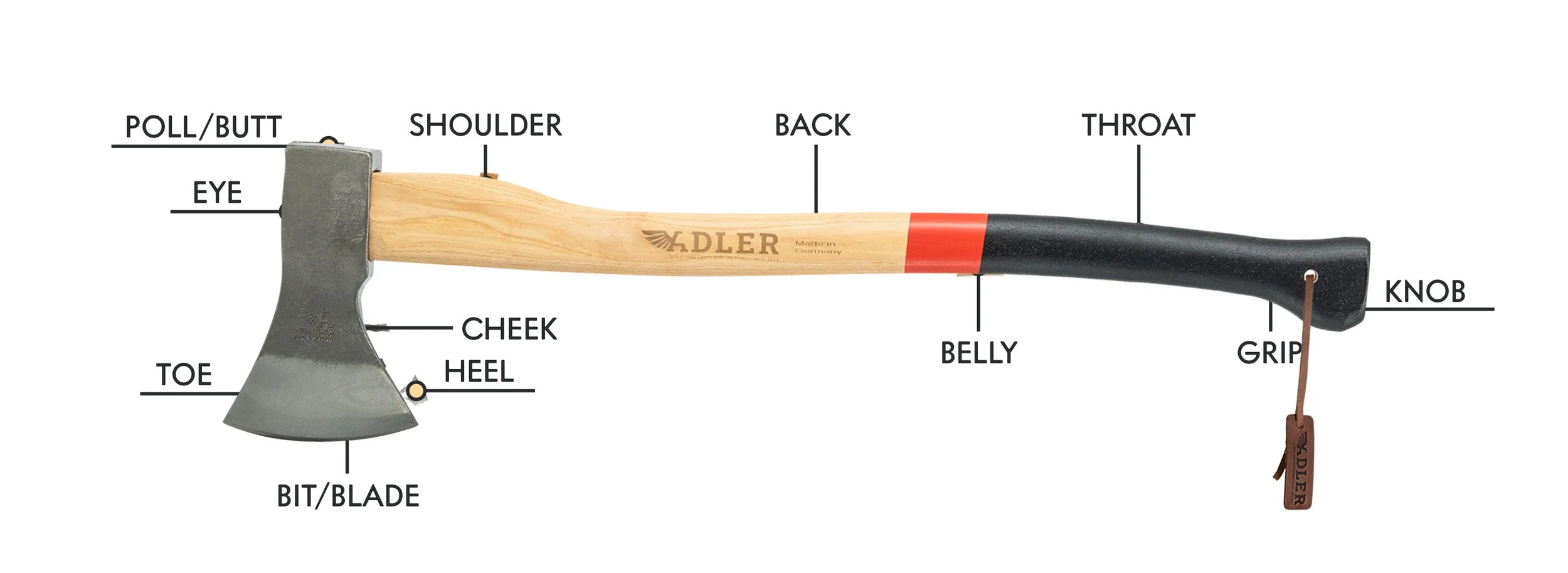

TERMINOLOGY

Axe Head

All Adler axes are forged from German C60 High Grade Carbon Steel, with a Rockwell hardness of approximately 47-55 HRC.

Axe Handle

There is a small variety of wood suitable for axe handles. Hickory is generally considered the best suited, being hard and dense, but with exceptional flexing strength. Ash is also a common choice, but not as ideal a wood as hickory.

Cutting Axe

An axe with a blade that features a shallow wedge angle, and is designed to be used for cutting, as opposed to splitting.

Dropforging

A process in which a smith controls a drop hammer to shape hot steel, as the hammer falls repeatedly onto the steel.

Felling Axe

Used to chop down trees by cutting across the grain of the wood.

Hatchet

A small, lightweight axe designed to be used with one hand.

Heat Treated

A process that involves heating or chilling the steel, typically to extreme temperatures, to achieve the desired result such as hardening or softening the metal.

Maul

A heavy, long handled sledge hammer with an axe blade on the opposite end of the head. Mauls are commonly used for splitting heavy wood.

Oil Hardened

A process where hot forged steel is quenched in an oil bath to cool and harden the steel. Similar to water-hardening, but less likely to cause small chinks and other minor defects in the metal.

Clear Lacquer Coating

A clear lacquer coating is applied to our axe heads for long term rust protection. As the axe is used, this coating will wear off. Our axes are made from high grade carbon steel, which is susceptible to rusting if not properly cared for. If one prefers to remove the coating, it can easily be done using a solvent, such as lacquer thinner. Lacquer thinner will not damage the metal, but will suck out any protective oils in the steel or wood handles. The head and handle should be oiled after a lacquer removal.

Splitting Wedge

A wedge, typically made from steel or aluminum, which is used to split wood. A sledge hammer is required to drive the wedge into the wood.

Turn-Around Hook

A small hook at the bottom of a maul's blade, which is used to turn over a log.

Water Hardened

A process where hot forged steel is quenched in a water bath to cool and harden the steel.